Procedure For Starting-Force

Sep. 11, 2018

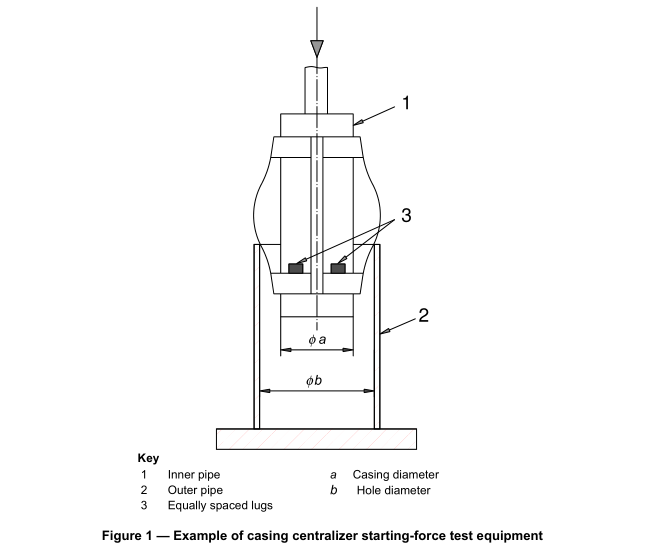

6.1 The starting force represents the maximum force required to insert the inner pipe into the outer pipe (after compensating for the weight of the inner pipe and attachments). It is determined as described in 6.2 to 6.6.

6.2 Install a Bow Spring Centralizer in new, fully assembled condition as shown in Figure1 on the inner pipe over four equally spaced lugs, with each lug protruding not more than 6,4mm ( 1 / 4 in) beyond the outer surface of the inner pipe.

NOTE Under field conditions, there are many different methods of attaching a centralizer to the casing. The starting and restoring forces for all types of holding devices may not be the same as the test results obtained using this procedure.

6.3 The test assembly shall be within 5° of vertical.

6.4 Lubricate the contacting surfaces with a petroleum-base grease before running the test.

6.5 With the bow spring centralizer resting on the edge of the outer pipe, apply a load to the inner pipe to pull the centralizer.

into the outer pipe.

6.6 Take readings of force used, from the time the load is first applied until the bow spring centralizer is completely inside the outer pipe. Report the maximum force as the starting force after compensation as in 6.1.

Oil machinery is our main products, the leading products include pumping unit, Casing Centralizer, drilling solid control series products and cementing accessories. Welcome to consult.